Innovation Leads the Trend, Quality Drives Value

Custom Single-Layer Roof Roll Forming Machine — Perfect Profiles Every Time

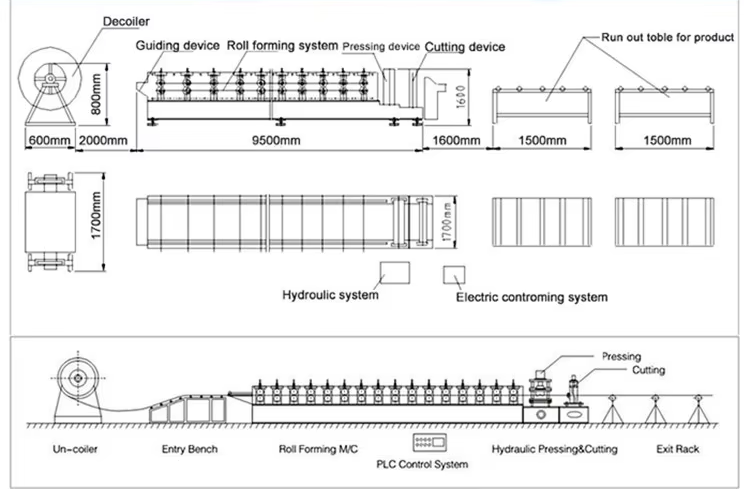

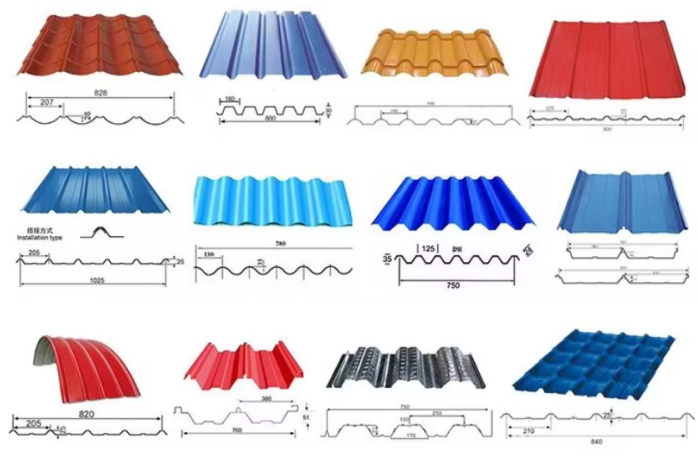

The industry-leading single-layer roof roll forming machine is engineered for modern architectural metal roofing systems, specializing in producing high-quality single-layer metal roof panels. Boost productivity and reduce labor costs with our automated single-layer roof roll forming machine — the smart choice for high-volume, precision metal roofing fabrication.

Investing in a high-performance single-layer roof roll forming machine is crucial for ensuring precision, speed, and durability. Our advanced single-layer roof roll forming machines are engineered to deliver consistent quality while maximizing operational efficiency.

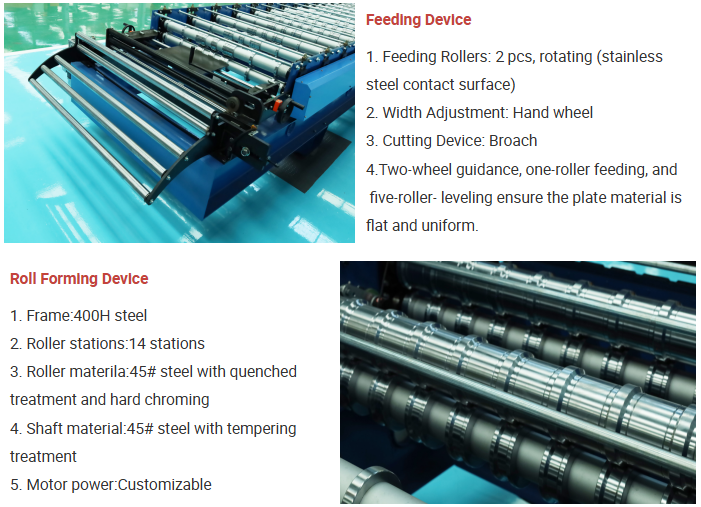

The single-layer roof roll forming machine is designed with advanced engineering and user-friendly operation in mind. The single-layer roof roll forming machine offers several advantages, including simple operation, convenient maintenance, easy mechanical adjustment, and fast mold replacement. Operators can quickly set up the single-layer roof roll forming machine to meet different roofing profile requirements, making production more flexible and efficient.

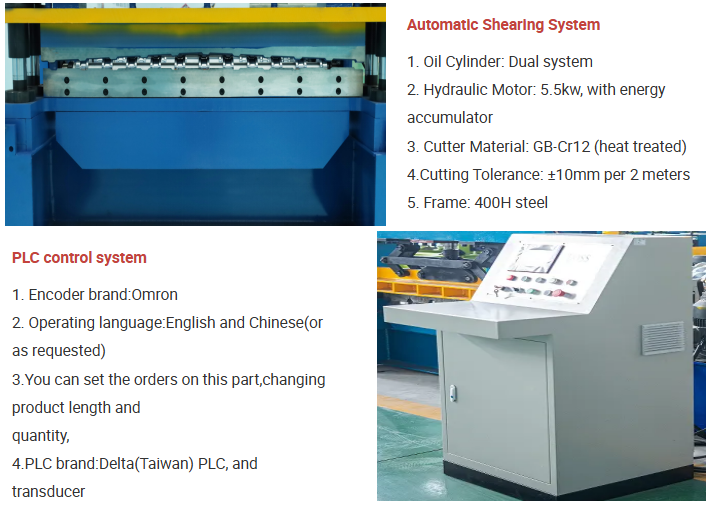

The entire automation system of the single-layer roof roll forming machine adopts a highly integrated control network, ensuring stable performance and superior reliability. With advanced electronic components and intelligent programming, the single-layer roof roll forming machine guarantees precise forming accuracy, stable speed, and consistent product quality during continuous operation.

The single-layer roof roll forming machine is equipped with high-level automatic control software that enables seamless production data monitoring and production information management. This intelligent control feature enhances production efficiency, reduces manual errors, and supports enterprise-level digital management. The result is a fully automated single-layer roof roll forming machine that improves productivity, ensures stable product quality, and reduces operational costs.

When operating a single-layer roof roll forming machine for tile production, proper die installation ensures optimal performance, as emphasized by leading roof roll forming machine manufacturers like ShanQuan. Here is a step-by-step guide to installing dies on a single-layer roof roll forming machine:

Install the Upper and Lower Dies: Mount the lower die directly onto the hexagonal rotary table of the single-layer roof roll forming machine. Secure the upper die to the bottom of the slide seat. Place a suitably thick shim to maintain uniform clearance around the dies once closed.

Adjust Die Spacing: Ensure the distance between the upper and lower dies matches the required tile blank thickness for precise forming on your single-layer roof roll forming machine.

Align the Remaining Dies: With the first upper die as reference, rotate the table and install the remaining five pairs of lower dies. Verify all die sets are uniformly positioned for consistent pressing.

Start the Machine Safely: Only initiate the single-layer roof roll forming machine after confirming all dies are correctly installed. Monitor the first few cycles to ensure proper tile thickness and die alignment.

Metal Single Layer Roll Forming Machine, Corrugated Sheet Rolling Machine, Ibr Roof Sheet, Roof Tile Making Machine | ||||

Formed Material | PPGI, GI, AI | Thickness: 0.3-0.8mm Width: 1500mm(customized) | ||

Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

Main body | Roller station | Up layer: 13 rollers Down layer: 15 rollers | ||

Diameter of shaft | 80mm solid shaft | |||

Material of rollers | 45# steel, hard chrome plated on the surface | |||

Machine body frame | 350 H steel welded | |||

Drive | Gear and chain transmission | |||

Dimension(L*W*H) | About 8500*1650*1500mm | |||

Weight | 6.5T | |||

Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

Power | Main power | 5.5kw | ||

Hydraulic station | 4.5kw with cooling fan for long time using | |||

Voltage | 380V 50Hz 3Phase | As your requirement | ||

Control system | Electric Box | Customized(famous brand) | ||

Language | English(Support multiple languages) | |||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

Forming Speed | 0-35m/min or as your requests | The speed depends on the shape of the tile and the thickness of the material. | ||

The roof panel forming machine should be used for metal roofs or walls, which is waterproof and durable, has a long service life, low production costs, and saves manpower and financial pressure. The following are applications scenario images:

.png)

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China