Innovation Leads the Trend, Quality Drives Value

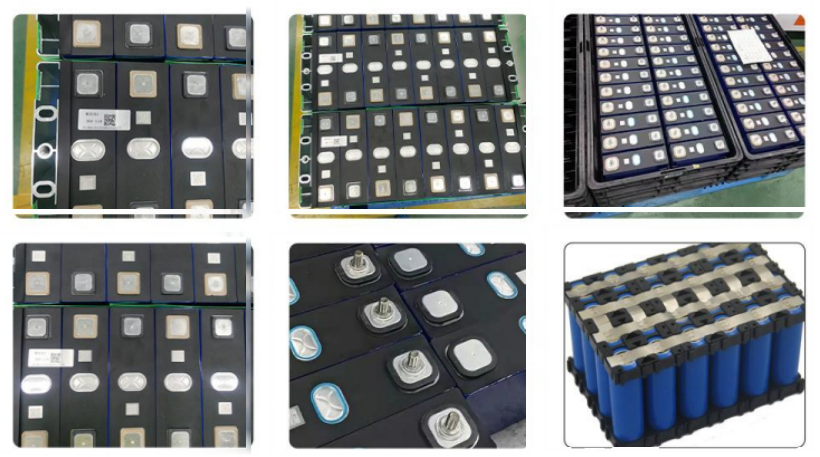

The lithium battery gantry continuous galvanometer welding machine uses the most advanced fiber laser in the world as the laser light source. This laser is specially designed for highly reflective materials (aluminum and copper). Combined with the gantry machine tool independently developed, designed and manufactured by our company, it has excellent rigidity and stability. It is driven by precision guide rails and equipped with a high-response servo motor, with high precision and high speed. It is mainly designed for fast and precise welding. The fiber laser has a series of advantages such as high beam quality, high brightness, high conversion rate, maintenance-free, stable and reliable operation, low operating cost and small size. It is the preferred equipment for welding aluminum, nickel and copper sheets.

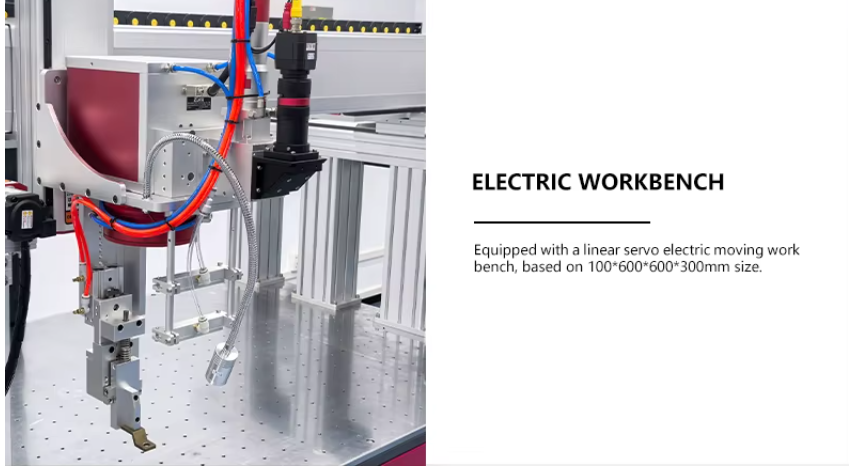

1. The gantry structure enables large-scale welding, supports simultaneous installation of multiple fixtures, and welds lithium battery packs of various specifications and models.

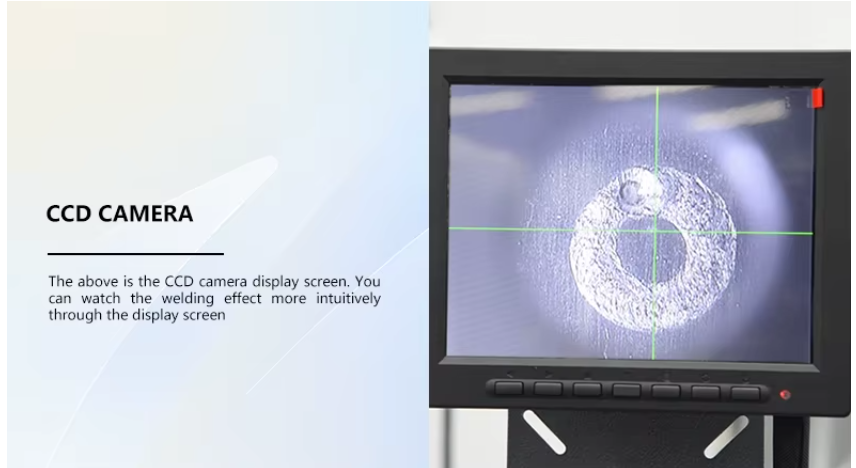

2. The laser weld spot is fine, with a small taper and high precision, resulting in a smooth, bubble-free weld surface.

3. Laser processing is pollution-free, with minimal heat impact and deformation. A cooling water system ensures the life of the laser device.

4. The galvanometer welding system boasts high efficiency, at least three times that of conventional laser spot welders.

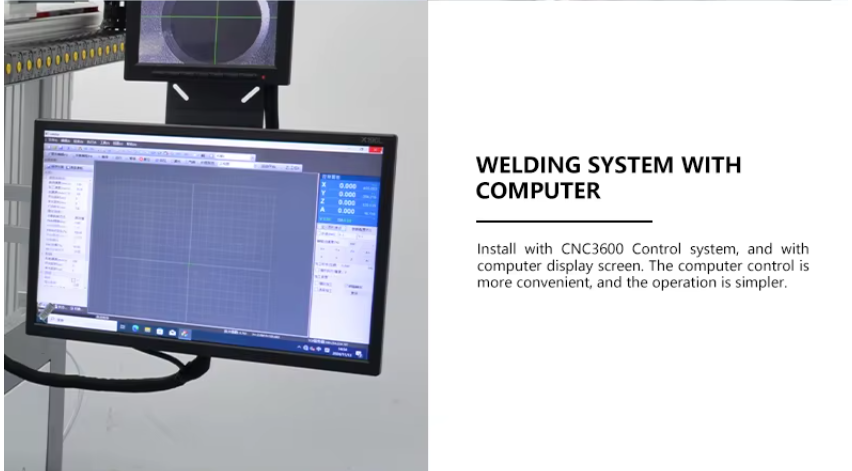

5. The industrial-grade PC provides stable performance and the welding system is easy to operate.

| Laser wavelength | 1080nm | Power adjustable range | 1%~100% |

Maximum modulation frequency | continuous | Laser power | 4000W(2000/6000 optional) |

| Fiber length | 15m | Fiber core diameter | 50UM |

| Cooling method | Water cooling | Laser Mode | Yv04 |

| Focal length F | 254/330/420mm optional | Repeatability | ±0.03mm |

| Rated power | ≤26kw | Operating temperature | 25℃ |

| Protection level | IP54 | Power | Can be customized |

| Maximum processing size | 740*740mm | Maximum height of workpiece | 500mm |

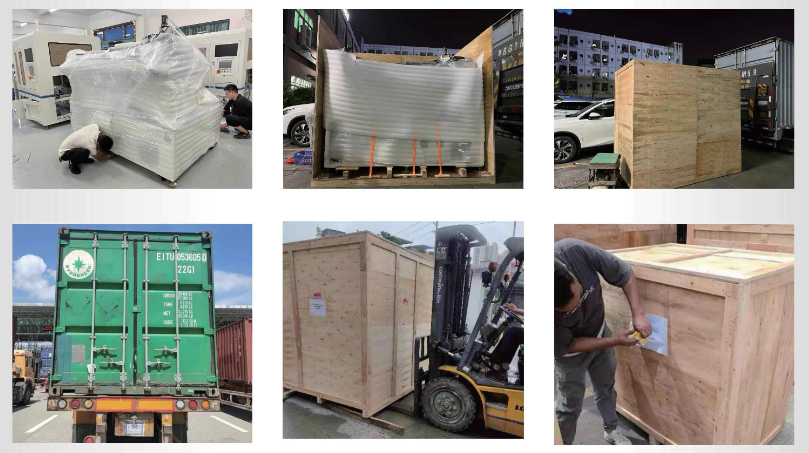

1. First wrap it with a layer of foam sponge to prevent the machine from being bumped during transportation .

2. Wrap a layer of waterproof film on the outside of the foam sponge to prevent water vapor from penetrating into the inside of the package, which will damage the precision of the machine and affect normal use .

3. Install a wooden bottom bracket at the bottom of the machine,wrap it with wooden boards, and finally fix the machine inside the wooden box .

4. Transported by car to designated ports or airports.

5.3-5 days by air, 20-30 days by sea (depending on the distance) .

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China