Innovation Leads the Trend, Quality Drives Value

Band saws are mainly used for sawing carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, acid-resistant steel and other alloy and metal materials. According to the structure, they are divided into horizontal and vertical types; according to the function, they are divided into semi-automatic, fully automatic and CNC. The horizontal type can be divided into double column type and scissor type.

Large low-frequency torque and stable output

High-performance vector control

Fast torque dynamic response and high speed stabilization accuracy

Fast deceleration and parking speed

Strong anti-interference ability

Looking for a reliable metal cutting machine for sale that delivers strength, accuracy, and durability? Our heavy-duty band saw cutting machine is built to handle the toughest materials with ease. Contact us today to get the best deal.

| SPECIFICATIONS | Units | G H4230 | GH4235 |

| Cutting circular | mm | 300 | 350 |

| Cutting rectangular | mm | 300*300 | 350*350 |

| Blade speed | m/min | 27,45,69 | 27,45,69 |

| Blade size | mm | 3505*27*0.9 | 4115*34*1.1 |

| Main motor power | kw | 3 | 3 |

| Hydraulic motor power | kw | 0.55 | 0.55 |

| Coolant motor power | kw | 0.04 | 0.04 |

| Machine weight | kg | 900 | 1000 |

| Overall dimension | mm | 1950*1100*1750 | 2100*1160*1850 |

.png)

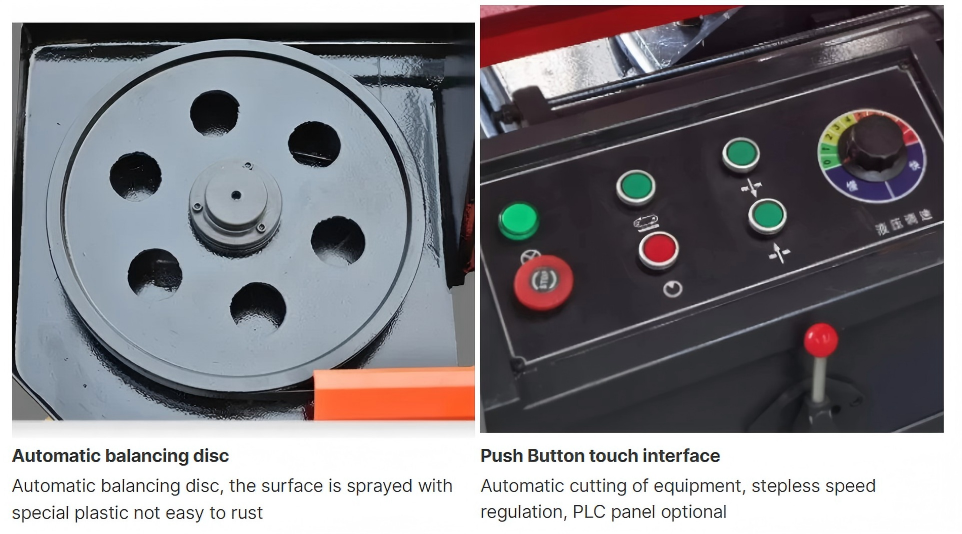

(1) The surface of the band saw wheel is quenched and cold-worked to improve the strength of the saw wheel surface and reduce the friction between the saw wheel and the saw blade.

(2) A 3-5mm thick rubber is applied to the surface of the saw wheel to effectively reduce noise. This method is mostly used on small band saws in furniture factories.

(3) The structure of the upper saw wheel is changed from spoke type to spoke plate type to make it less susceptible to vibration. The spoke plate type upper saw wheel adopts an integral casting structure, which eliminates or reduces the airflow rotation noise and eddy current noise generated by the rotation of the spoke type upper saw wheel, and the noise of the whole machine is reduced by about 3d B(A).

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China