Innovation Leads the Trend, Quality Drives Value

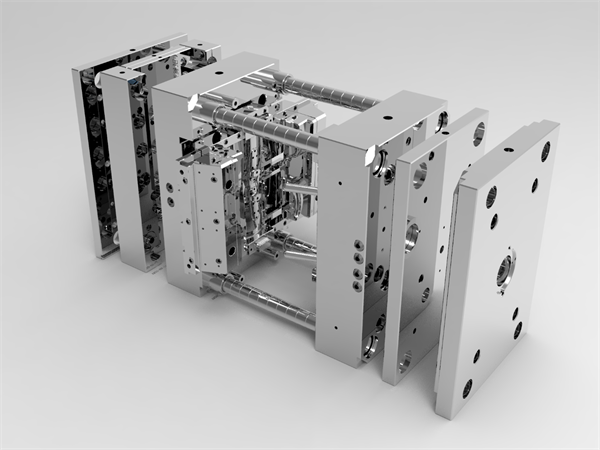

In modern industry, mold design and manufacturing plays a vital role in ensuring the production of high-quality components. With the advancement of digital technology, CNC machine tools have become indispensable in mold design and manufacturing, especially in the processing of critical parts such as cavities and cores. By relying on CNC machining, enterprises can achieve higher accuracy, which directly extends the service life of the mold and enhances production reliability.

At the same time, precision mold making has become a core link in maintaining competitiveness. CNC machine tools enable more refined operations in precision mold making, allowing for the creation of complex geometries with tight tolerances. This not only improves the dimensional accuracy of molds but also ensures consistency in repeated production.

Furthermore, mold design and manufacturing supported by CNC technology makes it possible to rapidly modify or upgrade molds with changing production needs. Such agility significantly improves efficiency and reduces time to market. When combined with precision mold making, manufacturers can better respond to customers’ requirements for customized solutions.

Ultimately, the integration of CNC machine tools into mold design and manufacturing and precision mold making enhances both efficiency and quality. By continuously refining these processes, the manufacturing industry can produce durable molds, reduce maintenance costs, and achieve sustainable development. Modern metalworking machinery manufacturers are driving innovation with advanced metalworking solutions that combine precision engineering with intelligent automation.