Innovation Leads the Trend, Quality Drives Value

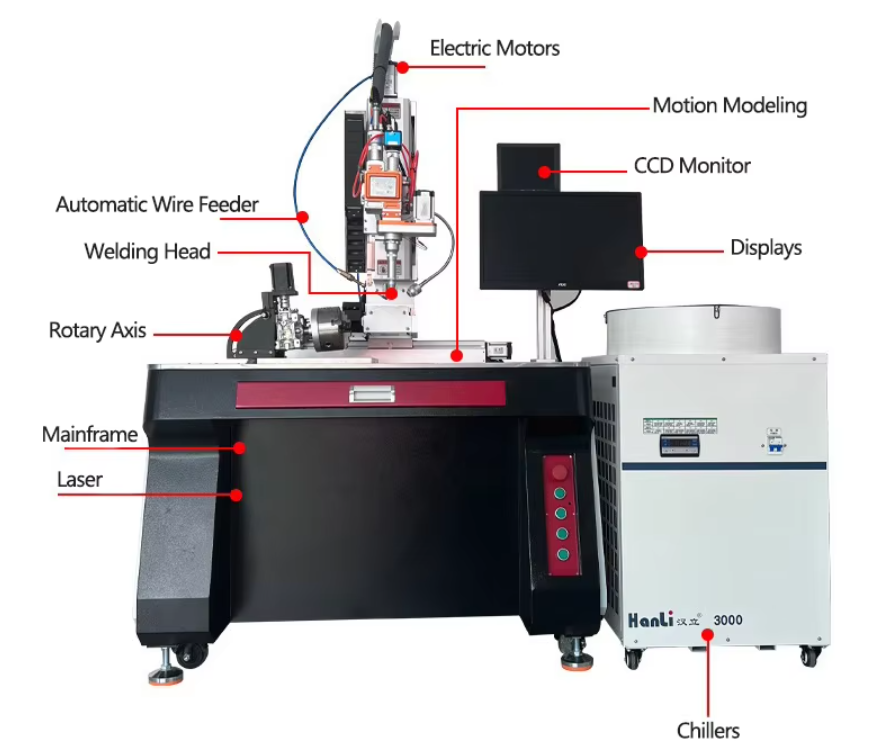

The platform laser welding machine is an automated device that uses a high-energy laser beam as a heat source to perform precision welding on metals or thermoplastics. Its core feature is a fixed or movable work platform (typically a CNC operating table) for precise workpiece positioning. This platform, combined with the laser welding head, enables efficient, high-quality welding.

This specialized continuous fiber laser welding machine is specialized for applications in traditional hardware, new energy and other industries. It offers advantages such as high peak power, excellent beam quality, a fine spot size, and flexible installation. The laser beam can produce a variety of spot shapes, enabling simultaneous processing of special-shaped spots, meeting various demanding welding requirements, such as mixed welding, and achieving precise and efficient welding. Customizable, detachable, and attachable jigs facilitate rapid integration into customer production lines.

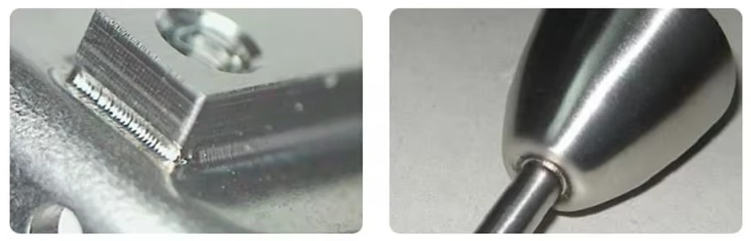

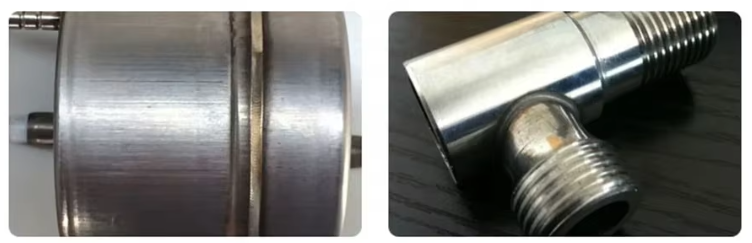

1. High Precision and Quality. The laser beam's extremely small focal diameter (down to micrometers) makes it ideal for precision welding, resulting in narrow welds, a minimal heat-affected zone, and minimal deformation. Controllable welding depth makes it particularly suitable for thin plates and tiny parts (such as electronic components and medical devices).

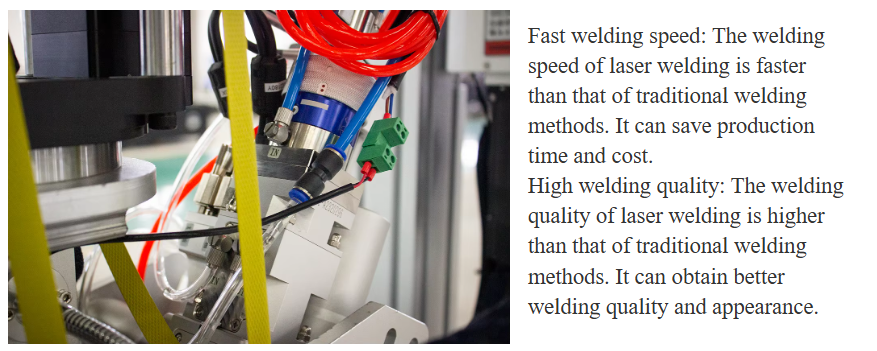

2. High Efficiency. Welding speeds far exceed those of traditional arc welding (reaching meters per minute), and the automated platform enables continuous mass production. Frequent wire/electrode changes are unnecessary, reducing downtime.

3. Strong Material Adaptability. It can weld highly reflective or difficult-to-weld metals such as stainless steel, aluminum alloys, titanium alloys, and copper, and even join dissimilar materials. Parameter adjustments accommodate varying material thicknesses (typically within a range of 0.1 to 10 mm).

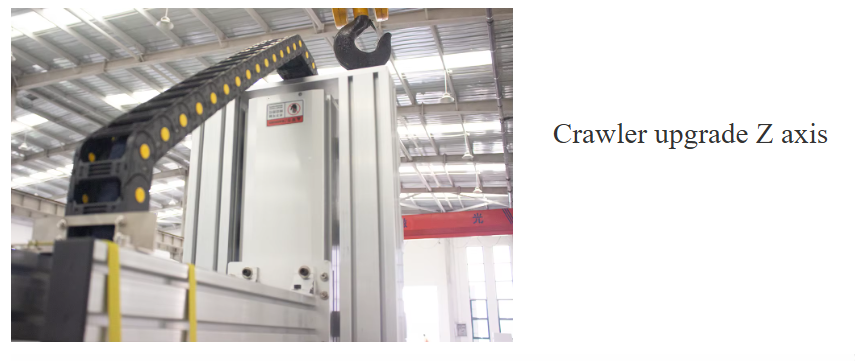

4. Automation and Intelligence. The CNC platform supports complex path programming (such as 3D curves) and boasts high repeatability (±0.01 mm). Vision systems and sensors can be integrated for real-time quality monitoring.

5. Environmentally Friendly and Low Energy Consumption. No smoke or dust, low noise, and no solder required, reducing pollution. Energy consumption is lower than traditional welding (electricity conversion efficiency can exceed 30%).

6. Non-contact processing. Lasers eliminate mechanical forces, preventing workpiece deformation and making them suitable for fragile or delicate components.

7. Flexibility and compatibility. The work platform can be customized (e.g., rotary table, multi-station fixture) to meet the needs of different industries (e.g., automotive batteries, jewelry, aerospace).

| Laser Power | 1000w (Option: 1000w, 1500w, 2000W,3000w) |

| Laser Fiber Wire Length | 10 m |

| Laser Output Power Adjustment Range | 10% - 100% |

| Spot Adjustment Range | 0-5mm |

| Effective Light Aperture | 16mm |

| Laser Head Weight | 0.71KG |

| Optical Fiber Interface | QBH |

| Wavelength Range | 1080±5nm |

| Intelligent Protection Function | Protective lens intelligent temperature control device |

| Collimating Focal Length | 50mm |

| Focal Length | 150mm |

| Core Diameter Of Supported Wire | 3.0mm |

| Maximum Wire Feed Speed | 80mm/s |

| Auto Wire Feeder Net Weight | 16.2KG |

| Auto Wire Feeder Dimension | 560*240*472mm |

| Machine Package Dimension | 1150*880*1400mm |

| Package Weight | 250KG |

Suitable for welding of Stainless steel,Iron sheet, Aluminium, Copper, Alloy, Steel, Diamond equivalent materials or dissimilar materials,cabinets,kitchens,stair elevators,shelves, ovens,stainless steel doors and windows guardrails,distribution boxes and other industries.

1. First wrap it with a layer of foam sponge to prevent the machine from being bumped during transportation .

2. Wrap a layer ofwaterproof film on the outside of the foam sponge to prevent water vapor from penetrating into the inside of the package, which will damage the precision of the machine and affect normal use .

3. Install a wooden bottom bracket at the bottom of the machine,wrap it with wooden boards, and finally fix the machine inside the wooden box .

4. Transported by car to designated ports or airports.

5.3-5 days by air, 20-30 days by sea (depending on the distance) .

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China