Innovation Leads the Trend, Quality Drives Value

The spindle of a horizontal milling machine is parallel to the worktable and in a horizontal position. In order to adapt to the milling of spiral grooves, the longitudinal worktable of the milling machine can rotate within the range of ±45° on the horizontal plane. This type of milling machine is called a universal horizontal milling machine to distinguish it from a general horizontal milling machine. A universal horizontal milling machine consists of a bed, suspension beam, lifting platform, worktable, saddle, spindle and base. If a turntable is added between the worktable and the slide of the horizontal milling machine, and the turntable can rotate in the horizontal plane to adjust a certain angle, it becomes a universal horizontal lifting platform milling machine.

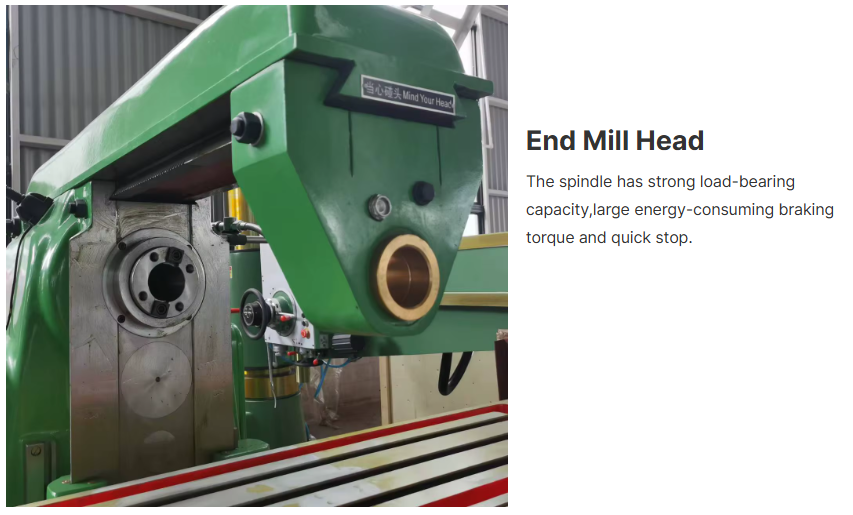

The spindle sleeve can be manually fed micro-feed, and is equipped with a limit device. The milling head can be adjusted 45° clockwise and counterclockwise;

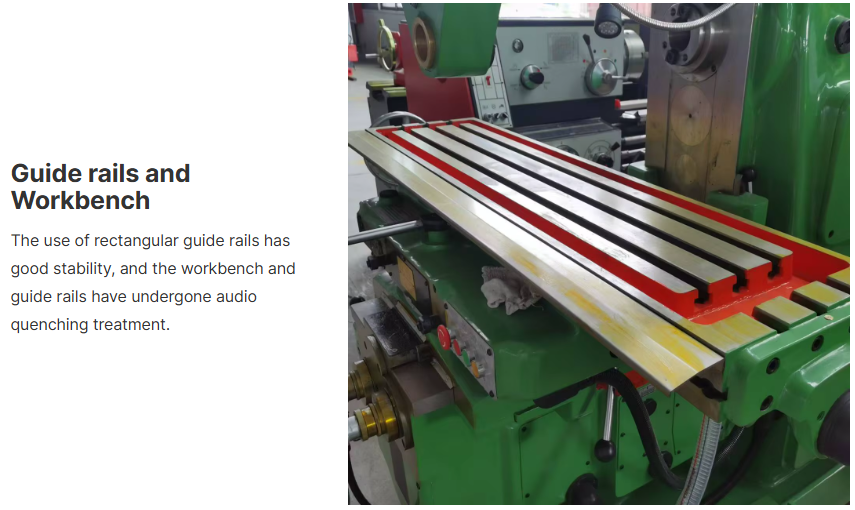

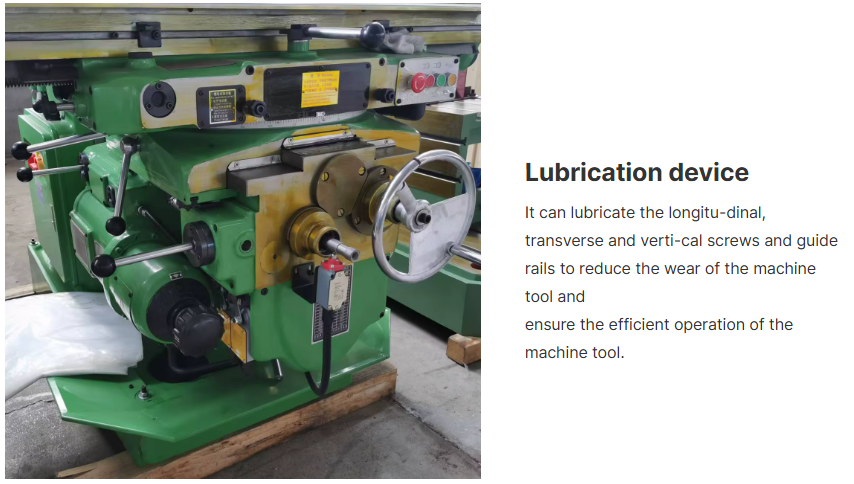

The worktable can be manually fed longitudinally and transversely and lifted vertically. At the same time, it can realize motorized fast feeding, motorized feeding and vertical motorized lifting in the longitudinal and transverse directions;

It adopts a 1200mm extended slide and a 1500mm extended worktable. The longitudinal stroke of the worktable can reach 1000mm, with a long stroke and stronger stability;

The main transmission and feed both adopt gear speed change mechanism, with a wide speed regulation range;

The spindle bearing adopts tapered roller bearing, which has strong load-bearing capacity, and adopts energy-consuming braking, with large braking torque, rapid stopping and reliable braking.

Main technical parameters | Unit | XK6132 | XK6140 |

Working table size | mm | 320X1325 | 400X1700 |

"T" type groove number, width and spacing | 3/18/70 | 3/18/90 | |

X-direction (workbench longitudinal manual | maneuver) | mm | 700/680 | 900/880 |

Y direction (sliding manual | maneuver) | mm | 255/240 | 315/300 |

Z direction (lift table vertical manual | maneuver) | mm | 370/350 | 385/365 |

Fast moving speed | mm/min | 2300/1540/770 | 2300/1540/770 |

spindle bore | mm | 29 | 29 |

Spindle pore cone | 7:24 ISO50 | 7:24 TSO50 | |

range of spindle speeds | r/min | 30~1500 | 30-1500 |

number of spindle speeds | steps | 18 | 18 |

Spindle axial movement distance | mm | 70 | 85 |

Maximum rotation angle of the vertical milling head | ±45° | ±45° | |

The distance from the spindle center line to the vertical guide rail surface of the bed body | mm | 350 | 450 |

Power of spindle motor | kw | 7.5 | 11 |

Machine tool shape size | mm | 2294×1770×1904 | 2556X2159X2258 |

Machine tool weight (net weight) | kg | 2900/3200 | 4250 |

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China