Innovation Leads the Trend, Quality Drives Value

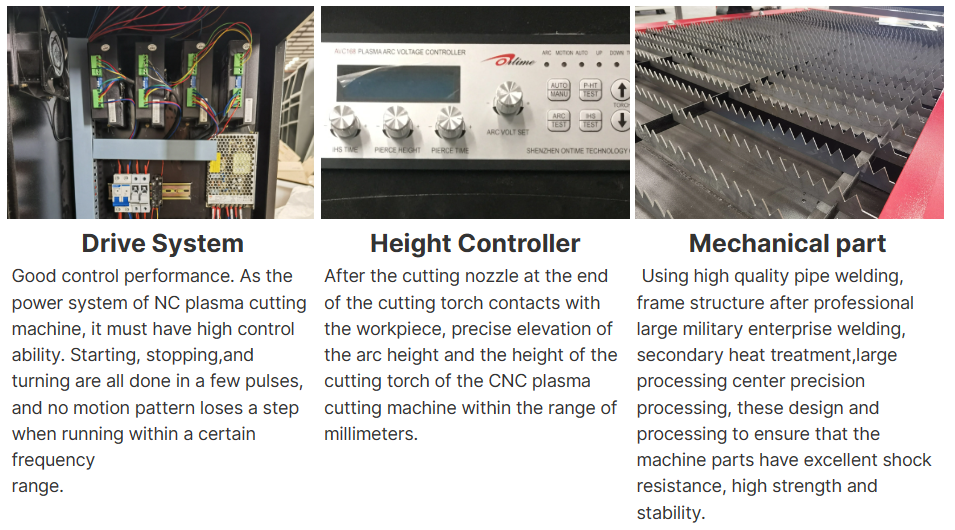

Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the workpiece cut, and uses the momentum of high-speed plasma to remove the molten metal to form a cut. It can cut various metals that are difficult to cut with oxygen cutting, especially for non-ferrous metals (aluminum, copper, titanium, nickel). Its main advantage is that when cutting metals with small thickness, the plasma cutting speed is fast, especially when cutting ordinary carbon steel thin plates, the speed can reach 5 to 6 times that of oxygen cutting, the cutting surface is smooth, the thermal deformation is small, and there is almost no heat-affected zone.

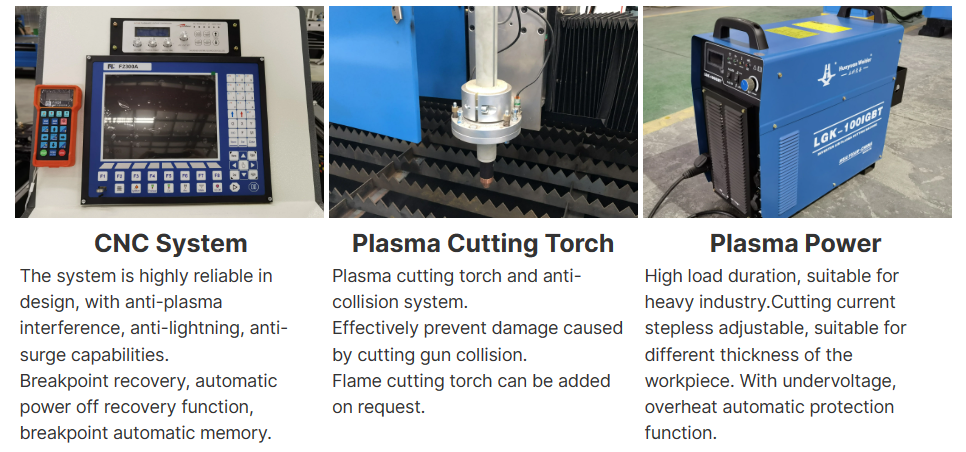

The frame adopts a fully welded structure, which is firm and reasonable, easy to operate, and durable.

The cutting speed is fast, and the precision is high. The cutting mouth is small and neat, and there is no slag. On the basis of the traditional CNC system, the control method for cutting is improved to avoid secondary finishing.

The metal cutting machine for sale is suitable for metal plates such as low-carbon steel plates, copper plates, iron plates, aluminum plates, galvanized plates, and titanium plates.

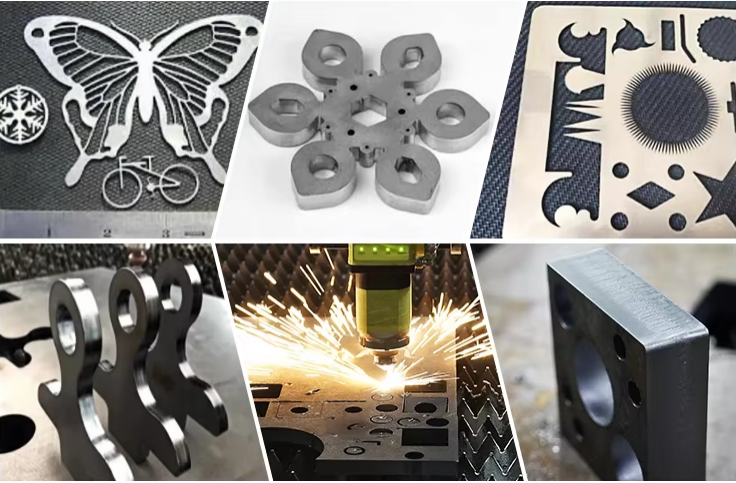

The CNC system has a high configuration. Automatic arc initiation, stable performance, and the arc initiation success rate reach more than 99%.

Support standard G code path files generated by software such as Wentai, Beihang Haier, ARTCAM, and Type3. The control system uses U disk to exchange processing files, which is convenient and fast to operate.

.png)

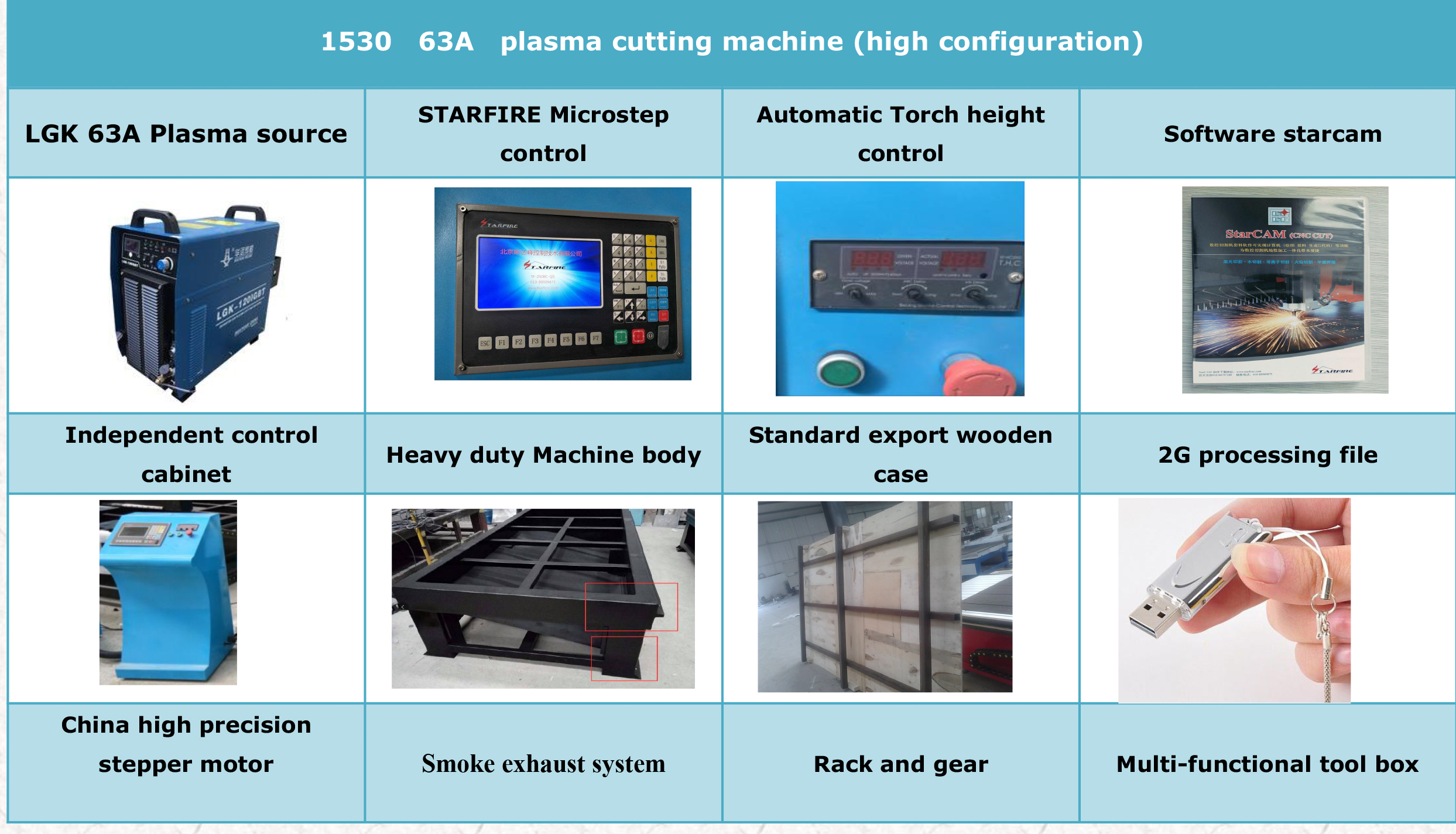

| Model Type | 2513 | 3015 | 4015 | 6020 |

| Cutting Width | 1300x2500mm | 1500x3000mm | 1500x4000mm | 2000x6000mm |

| Laser Media | Fiber Laser | |||

| Power | 1000w/1500/2000w/3000w | |||

| Wave Length | 1080nm | |||

| Min. Route Width | 0.01mm | |||

| Reposition Accuracy | ±0.05mm | |||

| Aiming Positioning | Red Dot | |||

| Voltage Requirement | 220V or 380V / 50Hz~60Hz | |||

| Linear Rail | Taiwan Lapping/Japan THK(optional) | |||

| Reducer | Japan Shimpo | |||

| Laser Source | RAYCUS/MAX/IPG(optional) | |||

| Cutting Head | WSX/Raytools | |||

| Servo System | France Schneider AC Servo System | |||

| Control System | Cypcut/Weihong NC Studio | |||

In recent years, foreign countries have developed a new technology called fine plasma or high-precision plasma, which we have introduced with good results. By improving the design of the cutting moment, the quality of the cutting surface of the workpiece is significantly improved. The verticality of the edge can reach 0-1.5°, which is especially beneficial to improving the cutting quality of thick plates. Due to the improved cutting gun, the electrode life has been increased several times. However, the distance between the cutting gun and the steel plate is relatively high, which requires the height sensor on the cutting gun to respond more sensitively and the lifting response of the cutting gun to be faster.

Therefore, it is an ideal method to use plasma to cut 4-30 mm steel plates, which can avoid the shortcomings of slow oxygen-acetylene cutting speed, large deformation, serious incision engraving, and serious slag hanging. Obtained blanks of materials such as stainless steel with a certain thickness.

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China