Innovation Leads the Trend, Quality Drives Value

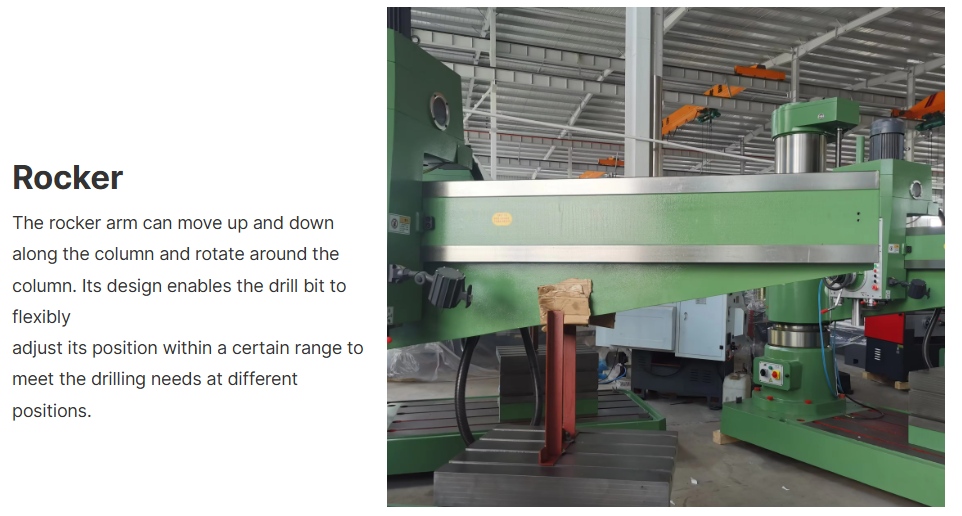

Mechanical radial drilling machines are generally deployed in production sites such as single-piece and small-batch production workshops for mechanical products, product assembly workshops, and mechanical repair workshops. The main variants of radial drilling machines are slide-type and universal-type. The slide-type radial drilling machine is formed by changing the base of the basic radial drilling machine into a slide. The slide can move along the guide rails of the bed to expand the processing range. It is suitable for boilers, bridges, locomotives and vehicles, shipbuilding, mechanical processing, and other industries. In addition to vertical and rotary movements, the radial arm of the universal radial drilling machine can also move horizontally. The spindle box can be tilted and adjusted on the radial arm to adapt to the processing of various parts of the workpiece.

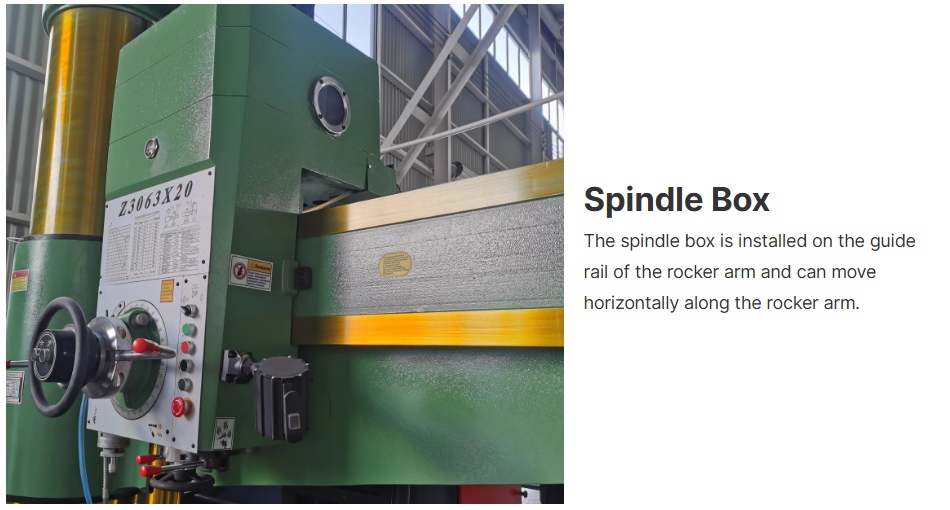

When machining, a special clamping device fastens the spindle box to the rocker arm guide rail, the outer column is fastened to the inner column, and the rocker arm is fastened to the outer column, and then drilling is performed. During drilling, the drill bit performs rotational cutting while feeding longitudinally. The movement form is:

The main movement of the radial drilling machine is the rotation of the spindle

The feed movement is the longitudinal feed of the spindle

The auxiliary movements are: the rocker arm moves vertically along the outer column, the spindle box moves along the length direction of the rocker arm, and the rocker arm and the outer column rotate around the inner column together.

| Item | Unit | Z3040x16/1 | Z3050x16/1 | Z3063x20/1 | Z3080x25 | Z30100x31 | |

| Maximum drilling diameter | mm | 40 | 50 | 63 | 80 | 100 | |

| Spindle center line to column bus distance | max | mm | 1600 | 1600 | 2000 | 2500 | 3150 |

| min | mm | 350 | 350 | 450 | 500 | 570 | |

| Spindle nose to base working space | max | mm | 1250 | 1220 | 1600 | 2000 | 2500 |

| min | mm | 350 | 320 | 400 | 550 | 750 | |

| Spindle travel | mm | 315 | 315 | 400 | 450 | 500 | |

| Spindle taper | / | Mohs4 | Mohs5 | Mohs5 | Mohs6 | Mohs6 | |

| Spindle speed range | r/min | 25-2000 | 25-2000 | 25-1600 | 16-1250 | 8-1000 | |

| Spindle speed | level | 16 | 16 | 16 | 16 | 22 | |

| Spindle feed range | mm/r | 0.04-3.2 | 0.04-3.2 | 0.04-3.2 | 0.04-3.2 | 0.06-3.2 | |

| Spindle feed level | level | 16 | 16 | 16 | 16 | 16 | |

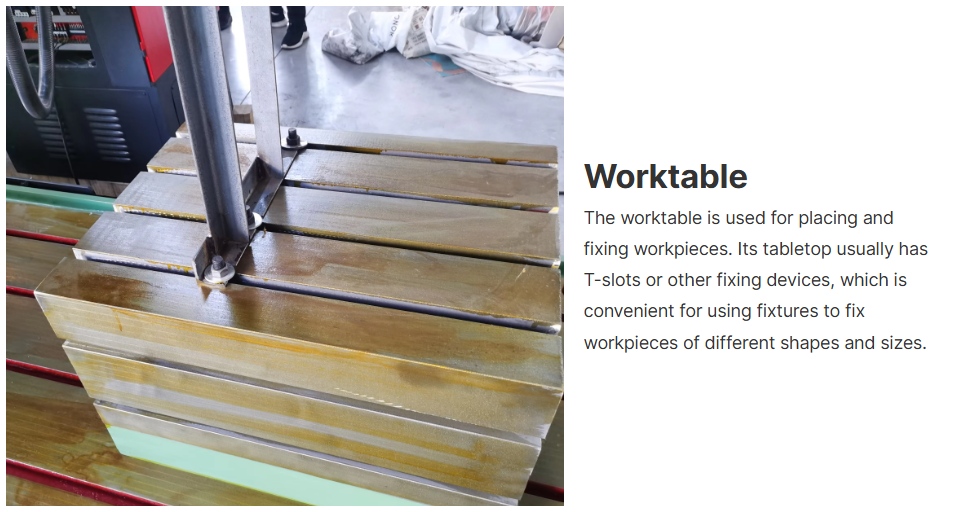

| Worktable size | mm | 630*500*500 | 630*500*500 | 800*630*500 | 1000*800*560 | 1250*800*630 | |

| Horizontal movement of headstock arm | mm | 1250 | 1250 | 1550 | 2000 | 2580 | |

| Spindle allows maximum torque | N.M | 400 | 500 | 980 | 1568 | 2450 | |

| Main motor power | kW | 3 | 4 | 5.5 | 7.5 | 15 | |

| Rocker arm lifting distance | mm | 580 | 580 | 800 | 1000 | 1250 | |

E-mail:

Tel/Whatsapp:

Address:

No.6 ShaKou Road of JinShui District, ZhengZhou City, Henan Province, China