Innovation Leads the Trend, Quality Drives Value

In today's manufacturing industry, the demand for precision, speed, and durability in sheet metal processing has never been greater. Traditional welding methods, while effective in certain applications, often struggle to meet the increasing complexity of modern designs. This is where the laser welding machine has become a game-changer. Specifically, the handheld model is emerging as the essential tool for sheet metal fabrication because it combines mobility with advanced accuracy. With its ability to operate flexibly across diverse working environments, the handheld laser welder minimizes distortion, reduces production time, and ensures high-quality results that traditional welding cannot consistently achieve.

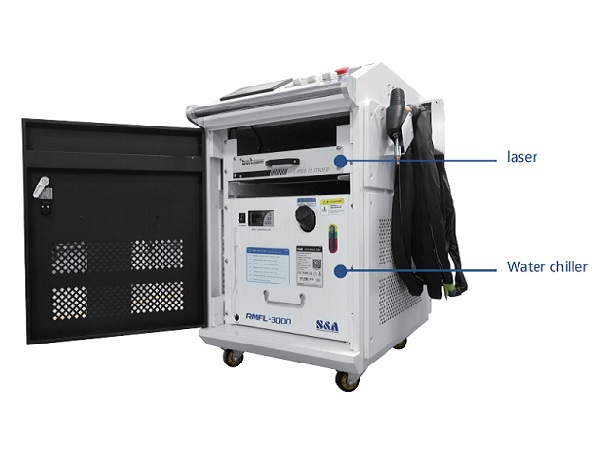

As one of the established metalworking machinery manufacturers, ShanQuan places great emphasis on engineering excellence. In its production workshop, a team of skilled engineers and technicians is dedicated to ensuring that every laser welding machine meets rigorous standards of performance and durability. The handheld models, designed with advanced technology, embody ShanQuan's mission to provide clients with solutions that enhance productivity while maintaining top-tier precision. Moreover, ShanQuan integrates environmentally friendly practices into its production process, reducing waste and energy consumption. This sustainable approach ensures that clients not only benefit from reliable machinery but also align their operations with modern environmental expectations.

When evaluating welding techniques for sheet metal fabrication, the advantages of handheld laser welding become immediately apparent. Below is a detailed comparison that highlights the differences:

Aspect | Handheld Laser Welding Machine | Conventional Welding Methods |

Mobility | Highly portable, adaptable to varied tasks | Limited by fixed equipment and workspace |

Welding Speed | Fast operation with minimal preparation | Slower, requiring extensive setup |

Heat Input | Low, preventing sheet deformation | High, often leading to warping |

Precision | Superior accuracy for fine welding details | Less precise, prone to imperfections |

Environmental Impact | Energy-efficient, reduced material waste | Higher energy use, more waste generation |

This comparison makes it clear why more manufacturers in the sheet metal industry are shifting toward handheld laser welding machines. The ability to weld faster, with greater accuracy, and with lower environmental impact represents a significant leap forward in production capabilities.

The introduction of handheld laser welding has not only improved the quality of sheet metal joints but has also transformed overall workshop efficiency. By minimizing post-weld refinishing and reducing errors, businesses can save significant time and resources. ShanQuan’s handheld laser welding machine is specifically engineered to support high-output operations without compromising accuracy. This allows companies to meet growing market demands with ease while staying competitive in industries where quality and speed are critical.

What distinguishes ShanQuan from other suppliers is not only its advanced machinery but also its unwavering focus on long-term client relationships. Beyond delivering high-performance equipment, ShanQuan provides technical assistance, after-sales support, and tailored solutions that evolve alongside client needs. The company's commitment to innovation and customer satisfaction makes it a reliable partner in the rapidly advancing field of sheet metal fabrication. Choosing ShanQuan's handheld laser welding machine is therefore not just an equipment investment, but a strategic decision that enhances long-term success.